Eliminate expensive tools while reducing labor costs through full automation

Enlightened

Engineering

Who we are

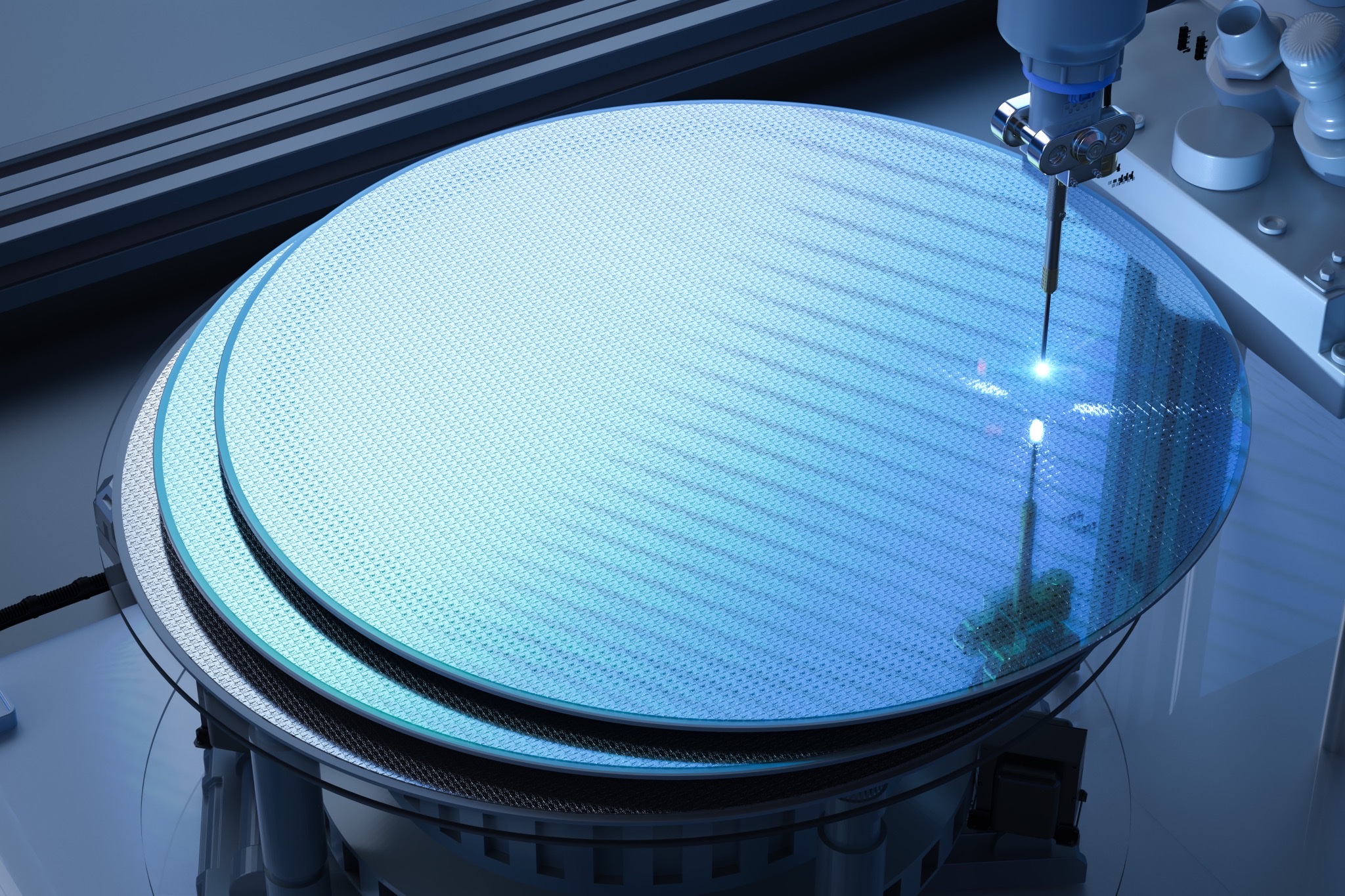

For industries driving tech forward, Halo is the most advanced laser-based manufacturing partner, unlocking the power of light for cleaner, smarter, more scalable production.

Performance

without capital

Performance

without capital

01 service

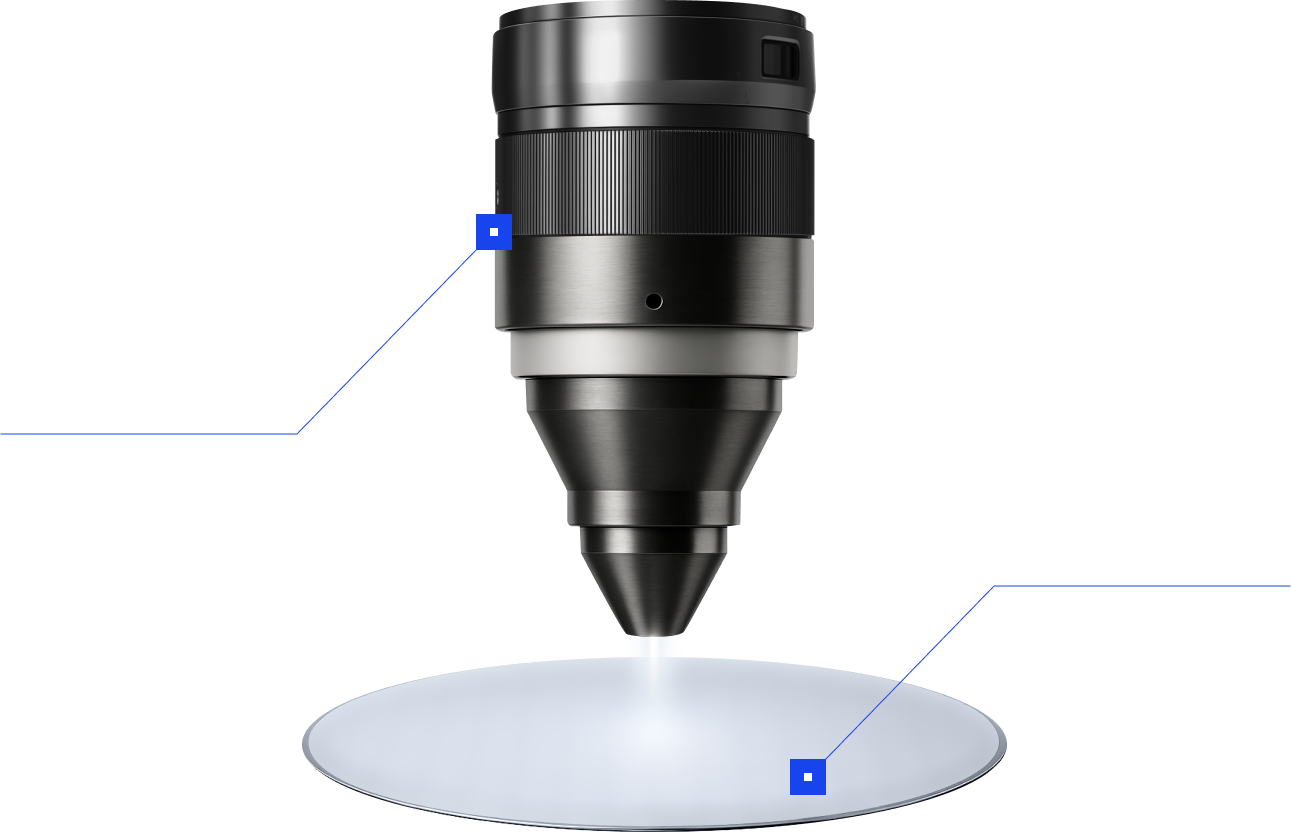

Laser wafering services

We deliver manufacturing excellence as a service—no equipment investment, just superior results.

02 service

SiC wafers

Production-grade wafers in multiple thicknesses—engineered to power tomorrow's breakthroughs.

Who we are

Partner with precision

Companies that invest in us: